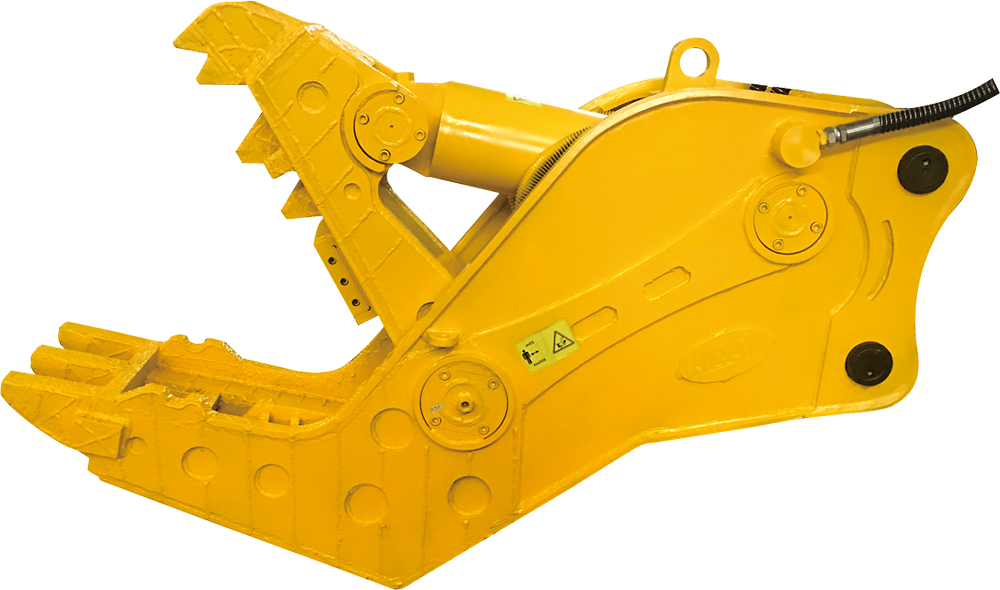

Specifications, models and technical parameters

| Model:Hydraulic pulverizers(inverted in cylinder) | |||

| Specifications | JQFSJ-220 | JQFSJ-260 | JQFSJ-35A |

| Hydraulic shear weight(kg) | 1620 | 18200 | 2250 |

| Maximum opening sizeMM | 850 | 880 | 920 |

| usage flow(1/min) | 200-240 | 240-280 | 220-240 |

| Tonnage of excavator | 20-24 | 25-28 | 30-36 |

| Hydraulic cylinder stroke | 470 | 470 | 470 |

| note: According to different working conditions of customers, more thrust cylinders can be selected for crushing operation. | |||

产品视频

Product use overview

The crushing forceps can accomplish a series of house demolition operations excellently, that is to say, the steel bar is separated from the concrete block, bent and loaded on the truck, thus obviously improving the work efficiency.

The working efficiency is two to three times that of the crushing hammer. The operation is fully mechanized, safe and time-saving.

The noise has no vibration and meets the environmental protection requirements. It is suitable for the demolition of urban and industrial parks.